Temperature-controlled Shipping Solutions

What is temperature-controlled shipping solutions?

Temperature controlled logistics specializes in the storage, preservation and transportation of cargo that is sensitive to atmospheric conditions and needs to maintain a certain temperature. This is imperative for many pharmaceutical products, as spoiled drugs can have serious consequences on the health and wellbeing.

Elevated temperatures or sub-zero temperature can affect the chemical stability of the medicine and may even alter its physical properties. This can come in the form of sedimentation and separation of emulsion systems. Due to the implications of improperly stored drugs, regulator demands have become more stringent and pharmaceutical companies need to be able to prove that they’re products are transported via a temperature controlled supply chain.

What are the critical touchpoints?

Logistics is complex, dynamic and ever-changing. As such, there is a wide array of touchpoints and hand-off processes between the various actors involved with the distribution of the product. As such, it is imperative that areas of risk are understood to ensure the proper handling of medicines. Different medicines and different transportation methods will come with their own unique touch points, but here is a rundown of the most common touchpoints that pose a risk to your medicine.

Preparing the product for transport to the shipper location – The primary transportation method may have temperature controlled storage facilities, but does the warehouse the product is stored in prior to transportation have similar facilities

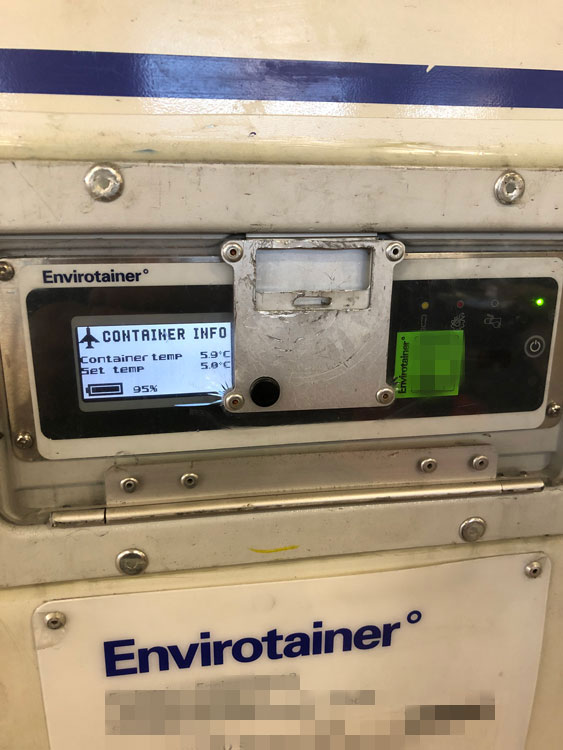

Transportation to the shipper location – Refrigerated vehicles or passive cooling systems will have to be considered to ensure the drugs will not be compromised en-route. Similarly, once the product reaches the shipper's storage facilities, will it have the required apparatus to ensure the safety of your medicines. Minimizing the amount of time the drugs spend at ambient temperatures is critical, especially in warmer climates. Walk-in cold storage rooms or dry ice can be used to help maintain the temperature of active and passive containers.

Physical loading – Ramp handling, covered storage, and potential delays need to be accounted for. Additionally, if an electrical connection to power is required, do all of the touch points have a compatible connection and ability to output appropriate wattage?

During transit - Finally, once the product is in the cargo hold of the aircraft or vessel – is it being sufficiently protected? The temperature controls may have been taken care of, but the positioning of the cold storage unit is just as important. Avoid storing the medicine near cargo doors and other cargo in general. Adequate circulation around the product is often required to reach a stabilized temperature. A notice to the captain should be issued to ensure that all variables are taken care of.